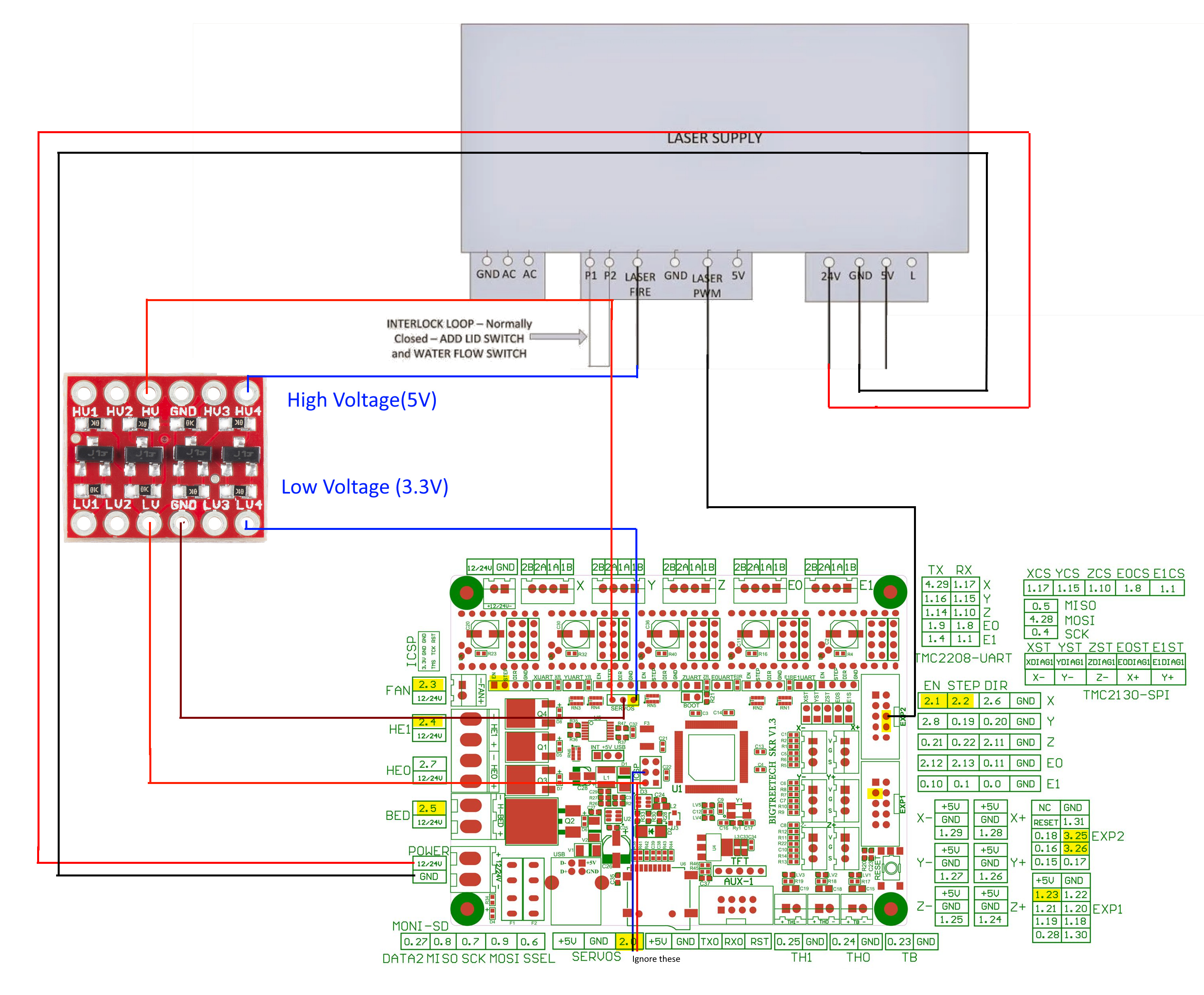

Stock motors are 9deg motors so 400 steps/rotation. Since I cannot get to motors to see what they are with out taking the machine further a part (I’d rather not), is it ok to move the jumper switch until I find the correct one with out damaging the motors?.It is common to leave the POT connected to the LPS( 5V/IN/Gnd) and use that to set your maximum avg current output(~18mA) and then you use one of the FET connections on the board to pull the LPS-L signal low for PWM control. Yes, you need to connect up your laser PWM control.

Does anything else need to be attached to the board for the K40 to work?.

0 kommentar(er)

0 kommentar(er)